Topics

Gas Quality Tracking

Natural gases of different origin may vary significantly in terms of their composition and hence their calorific value.

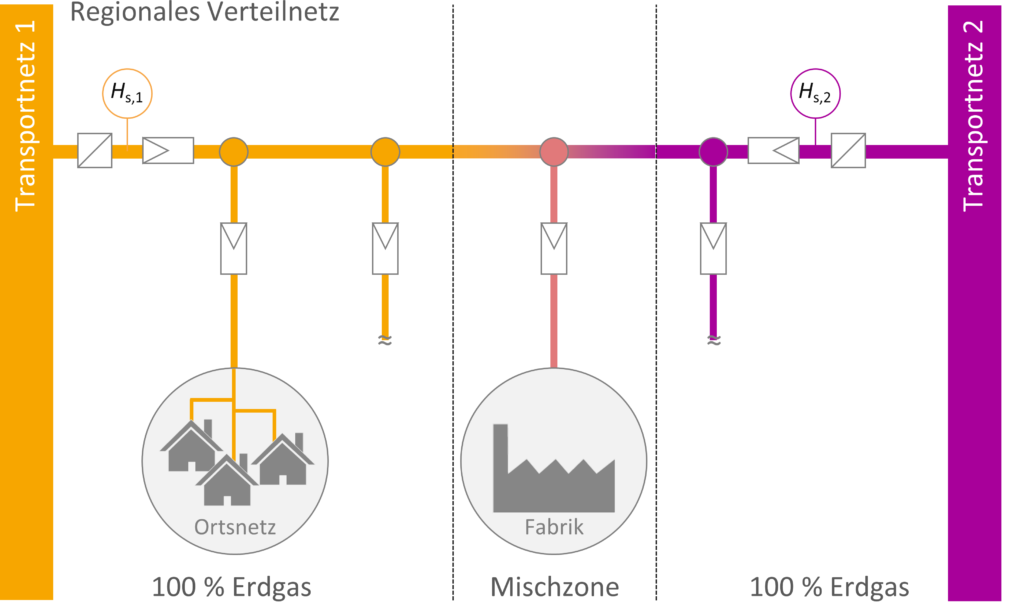

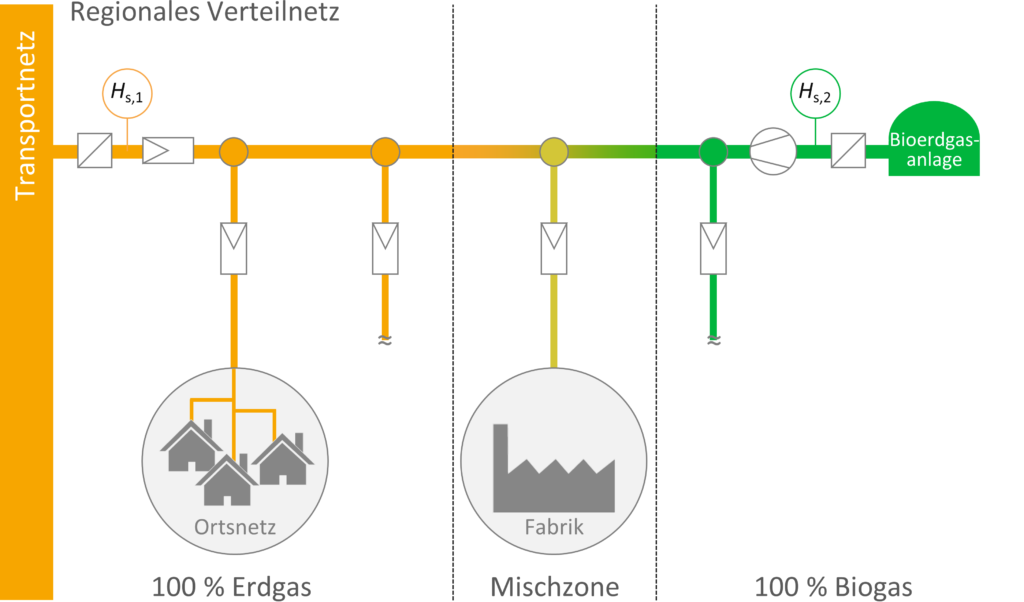

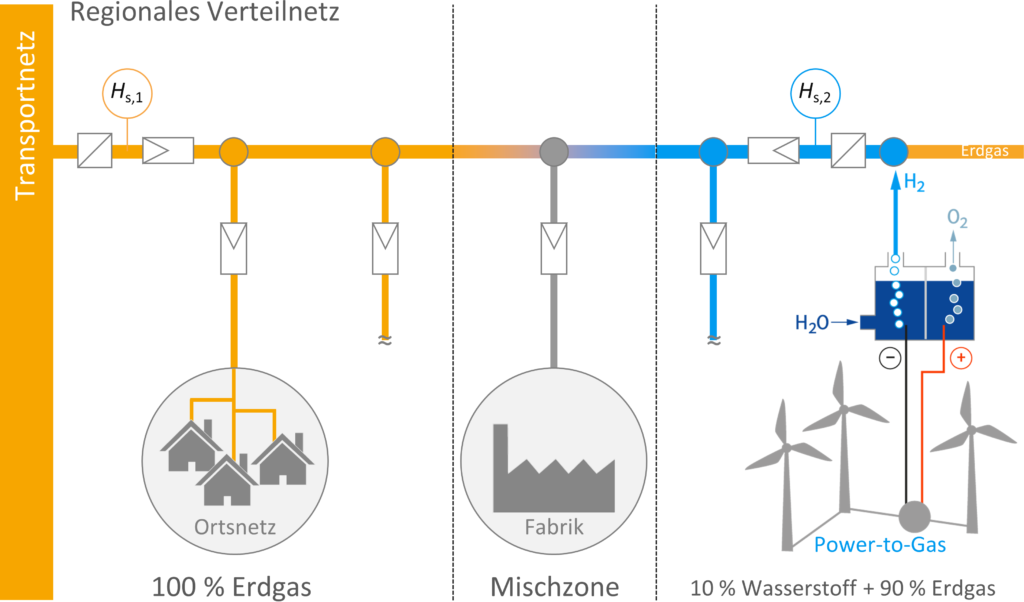

The calorific value of biogas, which is increasingly fed into grids, is usually 5-10 % lower than that of the natural gas prevailing in the supply area. The calorific value of hydrogen is even lower by a factor of 3 (per cubic meter). The end user consumption is usually measured only volumetrically, so how can the consumed energy be determined correctly?

Energy billing is usually based on an average calorific value (CV) for the respective supply area, as it is also described in the international standard ISO 15122. However, this practice is only possible within certain limits. In Germany e. g. the DVGW technical code G685 (gas billing) defines, that billing with an average CV can only be applied if the injected gases do not differ by more than 2 % from the average value (billing CV).

If this limit cannot be met, so far the network operator has had no option but to measure the CV at each exit point, or to condition the gas; in the case of biogas, this is usually done by adding LPG (propane). Both options come with significant costs for the grid operator.

With SmartSim, a simple and efficient solution is available for determining the calorific values at the exit points of the grid on the basis of gas quality tracking

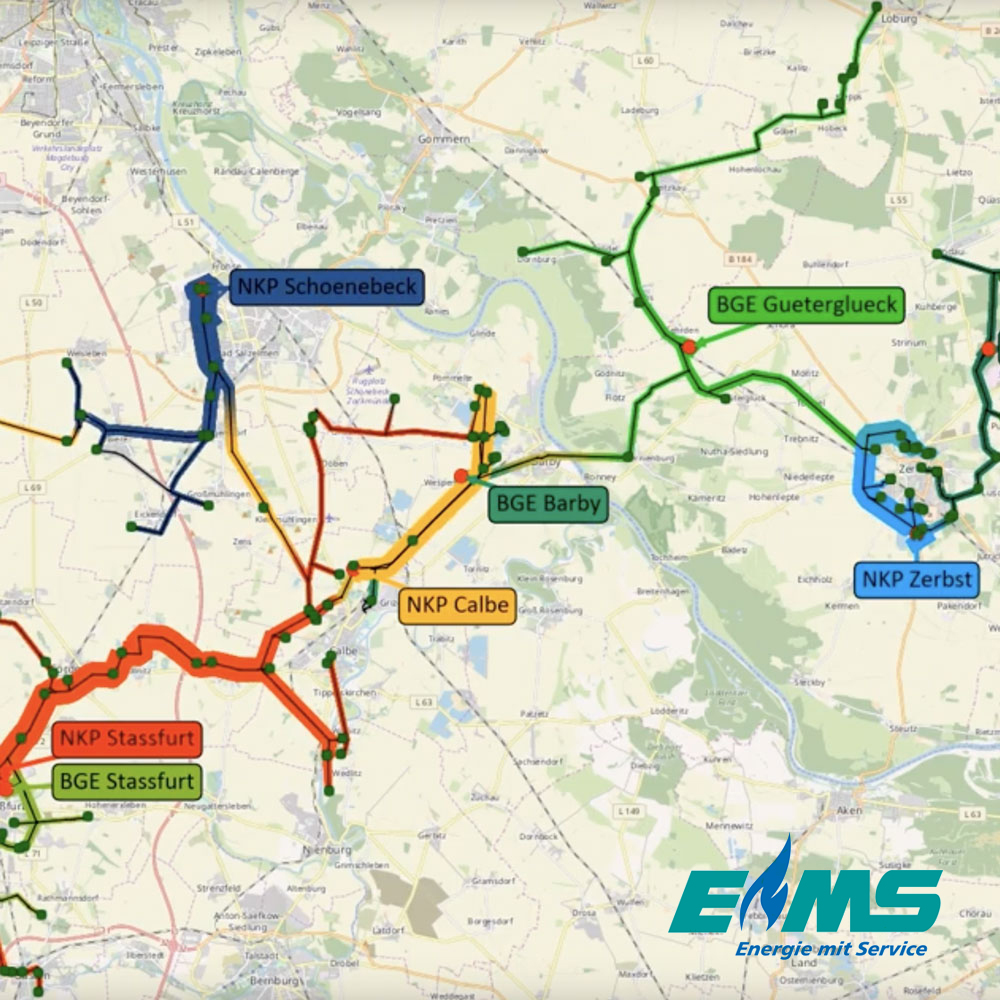

Regionales Verteilernetz

How does gas quality tracking work?

The use of SmartSim requires a number of input data. In addition to information about the grid topology, measured values are required for the calorific value at the entry points and for the volume flows at all entry and exit points. For distribution grids, where volume meters are often not available at the exit points, the volume flows can be determined using standard load profiles (SLP). Further auxiliary variables, such as the measured pressures at the entry points, are also included in the calculation.

On the basis of this input data, which is generally available as hourly values, the flow condition of the entire grid is determined by way of simulation. A special algorithm is then used to track gas packets from the entry to the exit points. In this way, the gas composition and thus the calorific value can be precisely determined at each exit point. In practice, gas quality tracking takes place on a monthly basis, with the calorific value being determined as a volume-weighted monthly mean for each exit point.

The validation of SmartSim is based on a statistical method – the Monte-Carlo simulation. This method, which is performed in accordance with the ISO Guide to the Expression of Uncertainty in Measurement (GUM), is a metrologically recognized way of determining measurement uncertainty for complex systems. The input data are randomly varied according to their measurement uncertainty and the impact on the output properties, e.g. the calorific value, is calculated. Using a large number of simulation runs it is then possible to determine the resulting uncertainty for each exit point. In addition, the system is regularly verified with measurements. This may be done with the help of a mobile process gas chromatograph (PGC) or a mobile gas sample collector.

Applicable for transport and distribution networks

Thanks to its efficient calculation model, gas quality tracking with SmartSim can be easily applied to both transport and distribution grids. The highly accurate model for flow simulation was programmed in a standalone module – the SmartSim Kernel – which can be controlled from a graphical user interface. The short calculation times allow even highly complex grids to be calculated within an acceptable time frame.

An interface for data import and export can be flexibly configured for different data and file formats. This simplifies the data communication to upstream or downstream IT systems. The user interface can be operated intuitively.

Grid operators operators save costs when renewable gases are fed into the grid

By using a gas quality system like SmartSim, grid operators are able to operate their grid flexibly when different gas qualities are injected. In the case of biogas, the calorific value no longer needs to be adjusted to the calorific value of the natural gas by adding propane. This can lead to considerable cost savings. In addition, additional CO2 emissions are avoided, as propane is known to have a negative impact on the carbon footprint, which is supposed to be improved through the use of biogas.

A great potential is seen in the power-to-gas technology. The hydrogen generated from renewable power can also be tracked with SmartSim and thus end customers in the grid can be invoiced in accordance with current technical rules.