GasCalc

GasCalc calculates gas properties of natural gases, LNG and renewable gases

The exact knowledge of physical properties of natural gases is important for many technical applications. This applies, for example, to the billing of delivered energy, the determination of CO2 emissions, the design of gas transport facilities or the optimization of gas appliances.

GasCalc is a software tool for easy and prompt calculation of all key properties of natural gases, LNG, biogases or hydrogen. The program is based on complex, high-precision calculation methods and complies with international standards. It has therefore become the standard program for calculating natural gas properties. Users of GasCalc include energy suppliers, grid operators, engineering companies as well as metrological institutions or research institutes.

Precise calculations made easy

Due to the user-friendly interface, the program can be used intuitively. Thanks to its modular structure and flexible integration in Microsoft Excel, users can also tailor applications to their specific needs. Following installation, more than 100 functions are available under Excel and may be selected from a menu. Numerous application examples demonstrate how the program is used.

GasCalc Download

You can download the GasCalc software via the link below. The download as well as the installation of the demo version are initially free of charge. After receipt of your binding order, the version can then be activated by e-mail via a license file generated by us. We will be happy to submit an offer. Please contact us by mail at info@gascalc.com.

Links

| GasCalc modules (calculated properties) | Examples of applications |

|---|---|

| 1. Gas properties according to ISO 6976 Calorific value, Wobbe index, normal density, molar mass etc. | •Energy billing, conversion of reference conditions (calorific value, normal density) • Monitoring/compliance of gas quality with specifications according to EN16726 |

| 2. Combustion Air requirement, exhaust gas analysis, etc. | • Design/control of combustion processes |

| 3. CO2 emission factor Calculation based on a full gas analysis or based on a simplified analysis (calorific value, normal density, CO2 fraction) | • Determining CO2 emissions according to DVGW Code of Practice G693 as part of emissions trading |

| 4. Methane number Calculation according to EN16726 based on a full gas analysis or based on a simplified analysis (callorific value, normal density, CO2 fraction) | • Avoiding “engine knock” in gas engines/small-scale cogeneration systems • Compliance/monitoring of natural gas qualities at CNG filling stations |

| 5. SGERG-mod-H2 Thermal properties according to ISO 12213-3 (compression factor, gas law deviation factor, density) | • Energy billing – conversion of volume at operation conditions to normal conditions |

| 6. AGA 8 Thermal properties according to ISO 12213-2, caloric properties according to ISO 20765-1 (specific heat capacity, enthalpy, entropy etc.) according to | • Energy billing – conversion of volume at operation conditions to normal conditions based on a full gas analysis • Design of heat exchangers, pressure reduction and compression processes |

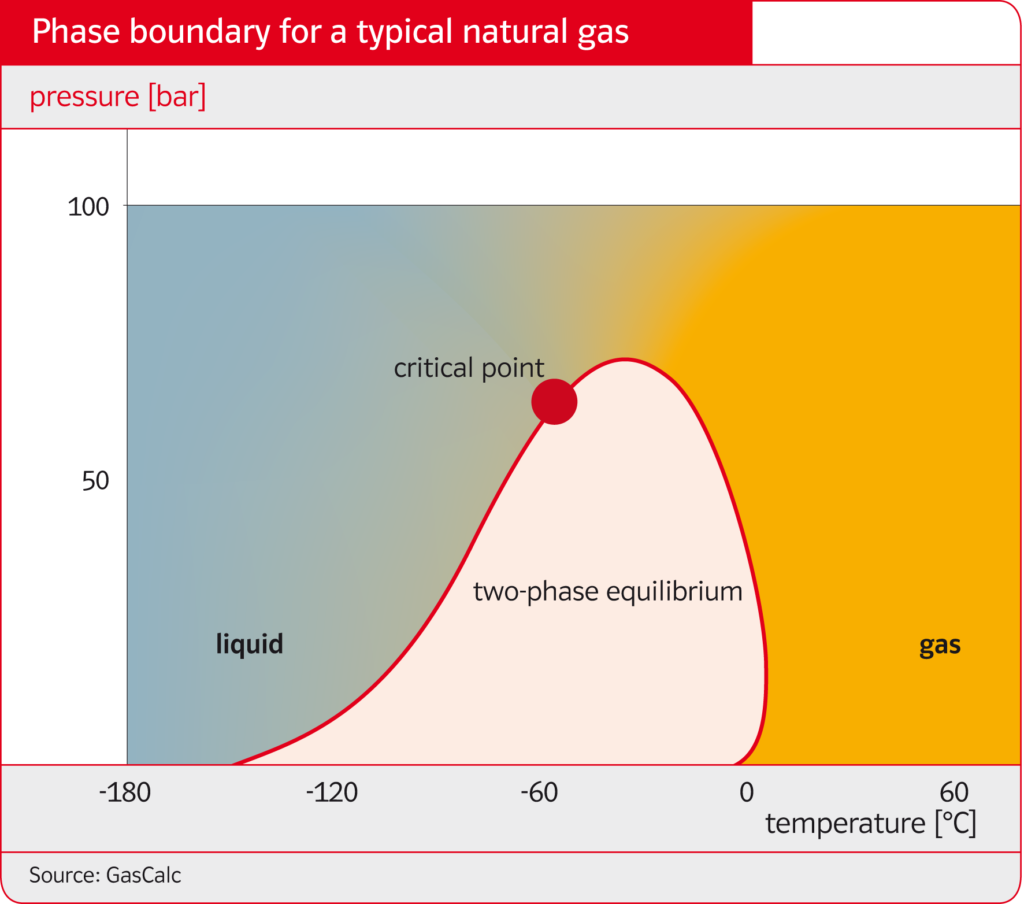

| 7. GERG 2008 reference equation Thermal and caloric properties according to ISO 20765-2/3 in the entire fluid region (gaseous region, liquid region, 2-phase region) | • Calculation for liquefied natural gas (LNG) • Calculation of dew points, boiling points • Calculations under extreme temperature and pressure conditions (storage facilities) • Calculation of pure component properties |

| 8. GERG Water Dew point according to ISO 18453 | • Monitoring/compliance of gas quality with specifications according to EN16726 |

| 9. Transport properties Dynamic viscosity, kinematic viscosity, thermal conductivity etc. | • Calculation of pressure losses in pipelines • Flow calculations (Reynolds number) |

| 10. Compressor Isentropic/polytropic changes of state on the basis of the AGA8 equation | • Design/optimization of natural gas compressors • Compressor efficiency |

| 11. Pre-heater Required temperature increase, preheating power and gas consumption of natural gasfired heat exchangers | • Design and operation of pre-heaters at pressure reduction stations |

| 12. Orifice plate calculations according to ISO 5167 | • Determining the normal volume for orifice plates |